Standard centrifugal pumps are one of the most trusted tools in the world of fluid transfer. Whether you're working in farming, factories, power plants, or water treatment, these pumps help move liquids safely and quickly. Because of their simple design and strong performance, they are used in almost every industry around the world.

You can learn what Industrial Standard Centrifugal Pump , how they work, their benefits, where it is used, and what makes them last a long time.

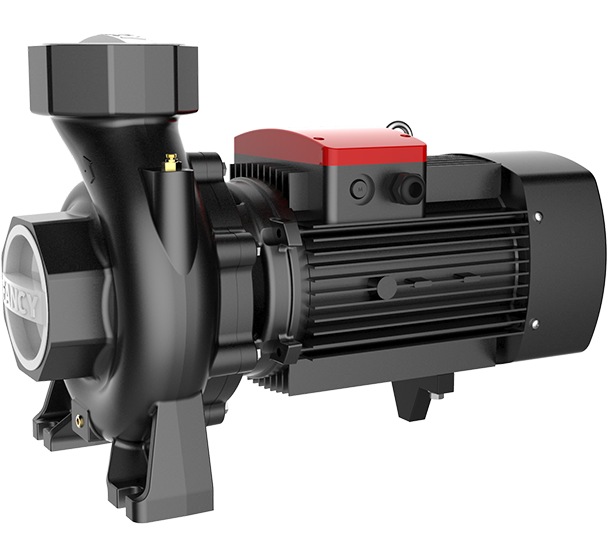

The FST Standardized Centrifugal Pump is a pump efficiency and performance for reliable fluid transfer. Designed by FANCY Pump Company and built below the modern EN733 standard, this pump comes with the best features. It offers each square and spherical car to match your setup. The YE3 high-performance motor works with IP55 safety, making it safe and power-saving. Its pump case has an anti-corrosive coating to fight rust. With a galvanized counter flange, bolts, nuts, and gaskets included, setup is easy. A strong bearing and a wear-resistant seal help the pump last longer, even under tough conditions.

A standard centrifugal pump is a machine that moves liquids from one location to another using spinning energy. It works like this: liquid enters the pump through the center, called the "suction quit." Inside the pump, there's a fast-spinning component referred to as an impeller. When the impeller spins, it pushes the liquid out through the sides of the pump. This creates a wave and stress that moves the liquid to where it desires to move.

The spinning of the impeller makes the liquid take advantage of energy. This energy facilitates the fluid movement via pipes to its final destination. Because of their easy parts and clear operating approach, centrifugal pumps are easy to use and install. One of the biggest motives those pumps are so not unusual is their potential to move large amounts of liquid without using a high amount of power. They work first-class with skinny beverages like water, milk, chemical, and oil.

Standard centrifugal pumps provide many benefits that make them perfect to be used in industries. They are efficient. They use less strength while moving numerous fluids, saving groups money on energy. That's best for both small businesses and massive factories.

These pumps are easy to put in and maintain. Their design is straightforward, so they don't spoil regularly. Even after they do, they're now not hard to restore. Workers don't need special education to deal with basic maintenance or replacements. That means less downtime and fewer issues.

They're flexible. That method you can use them with extraordinary types of liquids, at unique speeds, and in special locations. You can find them in easy water structures, dirty water coping with, oil shipping, or even in food and drinks factories.

Single-stage centrifugal pumps are cost-effective. Their elements are broadly to be had and not too pricey. This makes them a clever desire for corporations that want top-class without spending a high amount.

Standard centrifugal pumps are used in many places because they're smart and dependable. One of the most important uses is in water supply systems. Homes, farms, and cities use those pumps to transport water from wells, rivers, or storage tanks.

In factories and processing plants, they flow chemical compounds, coolants, and even hot drinks from one machine to some other. They help preserve everything, jogging smoothly and adequately. In the meals and beverage industries, unique forms of centrifugal pumps are used to move milk, juice, and other drinks in a smooth and careful manner. These pumps are crafted from secure materials that don't damage the food.

Power flora use them in cooling systems, where they assist in delivering cool water to machines that get hot throughout operation. In the oil and gasoline industries, they assist delivery of oil and fuels through pipelines. Even in wastewater treatment vegetation, trendy centrifugal pumps play a huge role. Horizontal centrifugal pump assists in taking away dirty water and ships it to locations where it is able to be wiped clean and reused.

The power and longevity of a centrifugal pump rely on the materials used to construct it. Most standard centrifugal pumps are made of forged iron, stainless steel, or plastic materials. Cast iron is strong and correct for clean water. Stainless steel is higher for chemical compounds and meals as it doesn't rust. Plastic pumps are mild and ideal for mild or unique beverages.

The impeller, that is the spinning part, ought to also be made from the proper cloth. If the liquid is thick or has small tough debris, the impeller must be very hard. Stainless steel or bronze impellers are regularly used in such cases.

Other design features that help pumps remain longer include mechanical seals to prevent leaks and strong bearings to maintain the components moving smoothly. Many pumps are also built with easy away with elements. This helps when it's time for cleaning or solving.

Another important part is the pump casing. This holds the whole lot collectively and publishes the liquid float. A suitable design reduces noise, saves electricity, and makes the pump last longer. Some pumps are made to deal with hot or cold drinks. These need special parts that gained't crack or bend with changing temperatures.

Choosing the right end suction pump is essential. If you choose the wrong one, it could damage quickly, waste strength, or not flow the liquid speedy enough. So, how do you pick the fine one?

Think about the kind of liquid you want to transport. Is it clean water, dirty water, oil, chemicals, or food products? Different pumps are made for different fluids.

Check how lots liquid you want to transport and how a long way it needs to move. This will assist you in finding the right length and energy. If the liquid wishes to move uphill or through lengthy pipes, you want a pump with more strain. Reflect on consideration on how regularly you'll use it. If the pump needs to run all day, each day, then you need a strong and terrific model. If you use it once pump in a while, a smaller pump may be sufficient.

You also have to examine your operating surroundings. If you're in a warm area, a pump with warmth-resistant parts is better. If you're in a chilly region, you'll need components that don't freeze.

Take into account the value of protection and spare elements. Pumps which can be smooth to keep shop money in the long run. For a satisfactory result, speak to a dependable pump dealer. They allow you to choose the best pump flow rate and head based totally in your task, fluid type, and price range.

If you're searching for a dependable name for water pumps and spare components, appearance no further than FANCY PUMP. This enterprise is known for its super product and user-friendly service. They specialize in the production and operation of diverse water pumps. Whether you need a pump for home, farm, manufacturing unit, or town use, they've got something for everybody.

They don't simply promote pumps — they design, test, and construct them using top-quality substances. Their crew is aware of what different industries want and works tough to meet those desires. FANCY PUMP also offers spare parts. In that manner, you don't need to update the whole pump if a small element breaks. Just change the element and keep going. This saves you money and time.

Customers from all around the international accept as true with them because they offer solid products, expert advice, and friendly support. Whether you're new to pumps or have years of enjoy, you'll find FANCY PUMP to be a beneficial accomplice.